Laying a Strong Foundation for Your Network Bidding

To make the most of your network bid, it’s essential to first establish an operationally efficient base. Much like mastering the basics before tackling complex mathematics, you need to build a solid operational groundwork for your network bid. This entails a fusion of technology and human expertise. Here are a few fundamental elements every supply chain should put in place before forming a procurement strategy.

Step 1: Establish a Robust Operating Environment

Every shipper needs a centralized system for the tracking, storage, and analysis of supply chain data. Depending on the complexity of your network, this might be a simple shared Excel document, an integrated TMS, or an extension of your company’s ERP or WMS system. At the very least, this system should allow you to analyze accessorial spend, track spending by carrier, and assess carrier performance in a clean, centralized manner. If it doesn’t, you need a better system.

As for human expertise, the personnel required will depend on the complexity of operations. Some networks may need entire teams dedicated to various facets of the supply chain, while others might manage with a few people overseeing multiple aspects. Regardless, every supply chain should have personnel focused on order management, procurement, and load planning and tendering.

Step 2: Define Success Through KPIs

When it comes to establishing a data-driven supply chain, figuring out which data to focus on isn’t always straightforward. Remember this guiding principle: Don’t start with the KPI, start with a business goal. Once you’ve defined what you want to achieve, you can select the KPIs that accurately measure success.

Step 3: Align Procurement and Operational Goals

With your team, processes, and measurements in place, it’s crucial to ensure everyone’s on the same page. This alignment is usually simpler for smaller shipping organizations, but larger ones might face inevitable debates between procurement and operations. It’s essential to strike a balance: service, but not at all costs. Your procurement strategy should reflect your corporate strategy.

Step 4: Understand the Current Market State and Future Trends

A solid understanding of the industry’s supply and demand dynamics, a comprehensive overview of the U.S. truckload market, and the most recent truckload market update and forecast are necessary to guide your procurement strategy.

Step 5: Refine Your Carrier Strategy

It’s crucial to have a diversified carrier base to avoid capacity risks and operational challenges. Consider using strategic partners, national carriers, regional carriers, and niche providers based on your unique requirements.

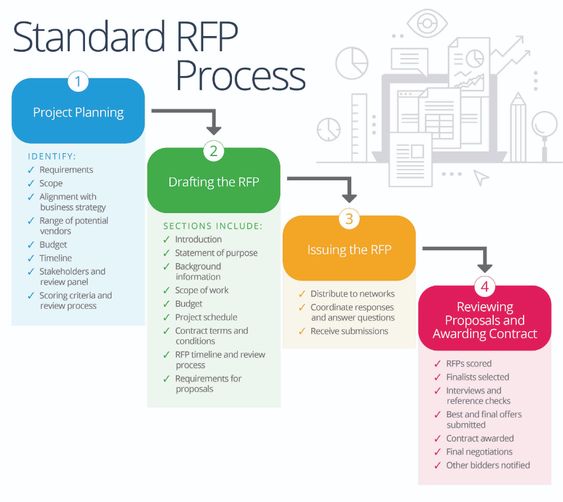

Step 6: Equip Your Team for the RFP

With organizational alignment, strategy, and market understanding, it’s time to conduct the bid. Make sure you have the right team and technology in place.

Step 7: Maintain Open Communication

After communicating the awards, confirm that each provider is aware of their award, understands your expectations, and agrees to their rates to avoid misunderstanding and potential re-bidding of some lanes.

In conclusion, while RFPs can be challenging, adhering to these steps can simplify the process and lead to smoother operations. Remember, there are no shortcuts to excellence in transportation procurement. It requires time, consistent focus, and a company-wide commitment to a shipper-of-choice strategy. But the investment is well worth the returns.